See How Our Poly Lumber Is Made

From the recycling bin to you in 6 simple steps.

1. Waste

is Collected

Recycled milk jugs and other HDPE materials are collected from waste management services. They are then washed and ground up.

2. It’s Recycled into Beads

The recycled material is run through an extruder and turned into small beads. The beads are then run through another extruder to add coloring and the UV Stabilizer.

3. Lumber

is Formed

The base material is then forced through a shaped die to create the correct size poly lumber boards for our Poly Kayak Racks. For us that’s: 1 ½” x 3 ½” for the racks, and 1 ½” x 5 ½” for the base.

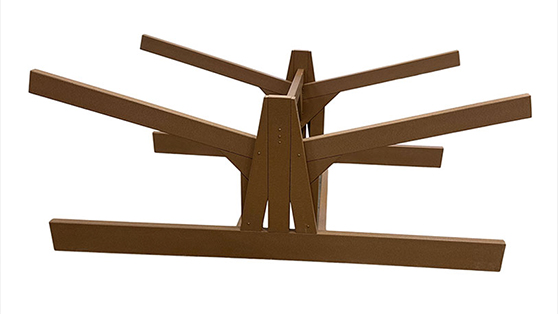

4. Your Poly Kayak Rack is Made

The poly lumber is then shipped to us where we cut each piece length, pre-drill the holes, smooth and round the edges of your kayak rack.

5. Your Poly Kayak Rack is Shipped

We then get your poly kayak rack packed to be shipped via FedEx to you.

6. Assemble

& Enjoy

Follow the included assembly instructions and within an hour you should be set to enjoy your new high-quality, poly kayak rack for years & years.

Now accepting Amazon Pay & Apple Pay for a fast and easy checkout process.

Shop Poly Kayak Racks

Shop our full selection of free-standing and wall-mounted poly kayak and SUP storage racks online now. If you have an unusual assortment or number of boats, give us a call at 1-715-534-2006. We’d be happy to talk through our various design options to find the one that would work best for your collection and property.